General Features

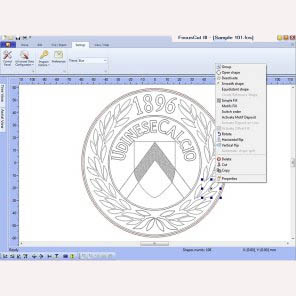

- Simple and rapid configuration of operating parameters

- Truly intuitive interfaces between user and work tools

- Management of five interface languages (Italian, English, French, Spanish, Portuguese)

- Display of the cutting plane of the machine on the work area

- Numerous display tools (zoom, show/hide, panoramic, grid…)

- Designed for Microsoft Windows XP, Vista, Windows 7, WIndows 10